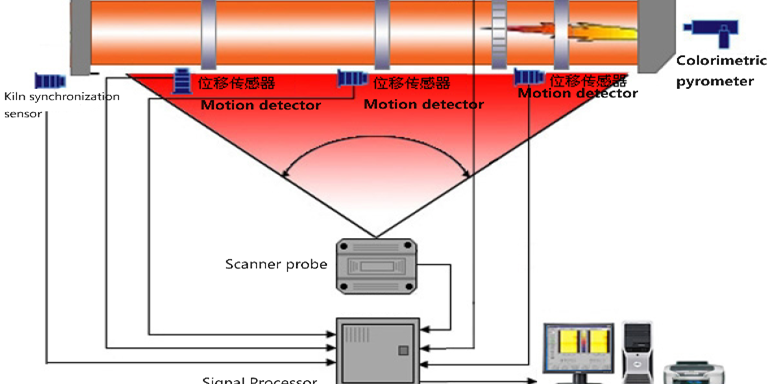

This Rotary Kiln Shell temperature monitoring system is suitable for cement rotary kilns, alumina kilns, ferroalloy kilns, pellet kilns and fertilizer kilns etc kiln shell temperature detection. Their sites are basically the same as those of cement kilns.

With this kiln shell temperature monitoring system, the temperature of the rotary-kiln surface is been detected in a non-contact manner via thermal radiation with high-resolution temperature measurement even at difficult-to-reach points of the kiln shell, it without any shadows.

The carcass scanner system software displays the entire carcass surface temperature expansion map on the monitor in real time, and refreshes one picture for each rotation of the kiln, with synchronous imaging.

This system is independently developed based on the world’s top scanner, Denmark Smith’s ECS/CemScanner system. It is an infrared scanning imaging system specifically used for rotary kiln temperature detection. The biggest advantage of this system is accurate, fast and long life temperature measurement. This system is specially designed for detecting the operating status of the rotary kiln. It can accurately detect hot spots caused by the shedding of refractory bricks of the rotary kiln to avoid high-frequency losses caused by kiln damage and greatly extend the service life of the kiln. Provide users with complete important parameters for detecting kiln operation. This temperature measurement system consists of a powerful ScanLine infrared scanner and dedicated detection software. Our company’s ScanLine line scanner is the same as the TMC5_HTP5 line scanner in Smith’s ECS/CemScanner system. It uses the infrared mercury cadmium telluride detector and amplification circuit of the American InfraRed company to ensure the stability and reliability of the system.

This system provides a variety of signal transmission interfaces, and provides wheel slip detection, cooling fan control module, optical fiber installation components, burning belt and shadow area detection module.